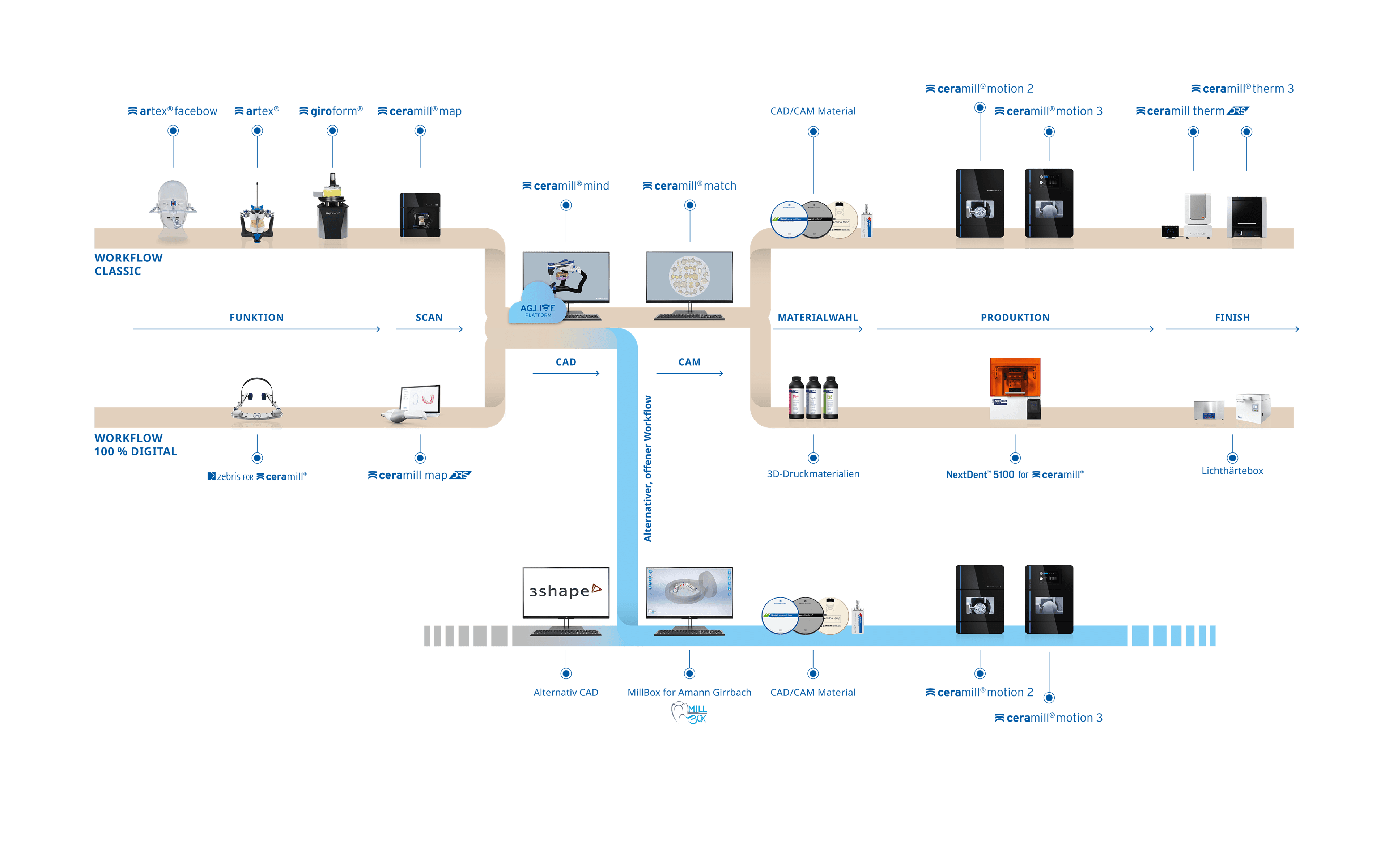

Open CAM Solutions for your Workflow

Customized solutions tailored to your individual needs drive us forward, especially in the field of Computer-Aided Manufacturing (CAM). We firmly believe, that successful laboratory processes rely not only on the performance of the products used but also on their integration through digital workflows.

From fully integrated to simply connected

Ceramill Match 2

We have always emphasized offering secure, validated processes in which all system components are optimally coordinated to guarantee excellent results. This is what our proven and fully integrated CAM solution, Ceramill Match 2, stands for, providing users with maximum process reliability. Learn more about Ceramill Match 2 here

MillBox for Amann Girrbach

Already a MillBox user or looking for a suitable solution for your existing setup? Thanks to the cooperation and flawless integration of MillBox for Amann Girrbach, this is now easily possible! Discover the suitable solution also outside the Amann Girrbach workflow. Maximum freedom, independent of your CAD software. Find out more about MillBox here

Open. Digital. Fully integrated. CAM.

At Amann Girrbach, you have the choice: Benefit from all the advantages of the fully integrated CAM solution, Ceramill Match 2, or connect your individual setup with our milling machines using MillBox for Amann Girrbach.

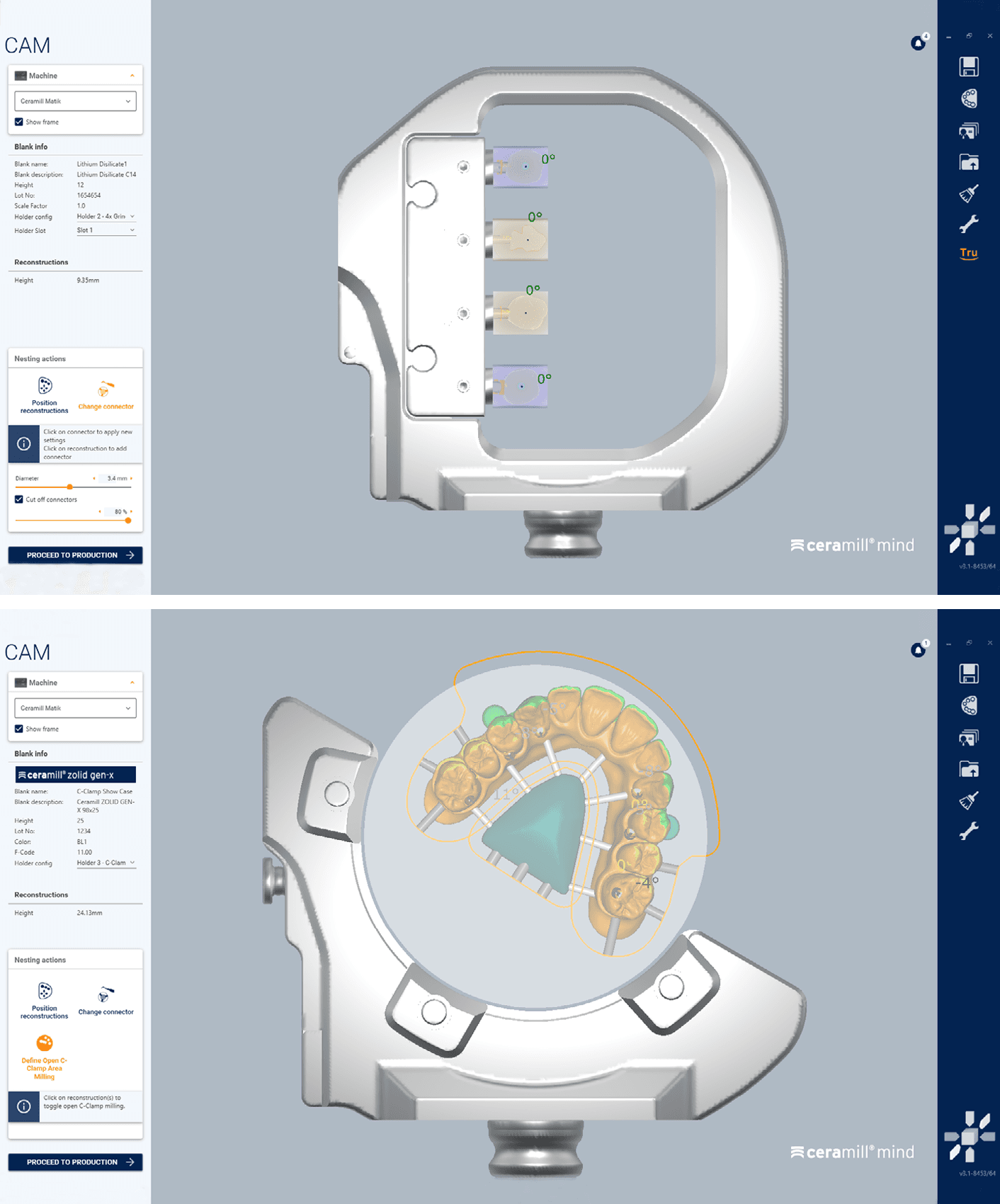

Ceramill Match 2

The automatic and user-friendly interface of the fully integrated CAM software, Ceramill Match 2, within the Amann Girrbach workflow, ensures reliable, efficient, and straightforward operation. CAM and milling expertise are not required for its use. Even users with less experience can quickly and easily create milling programs for various indications. Ceramill Match 2's sophisticated collision control and avoidance feature ensures the highest level of process security.

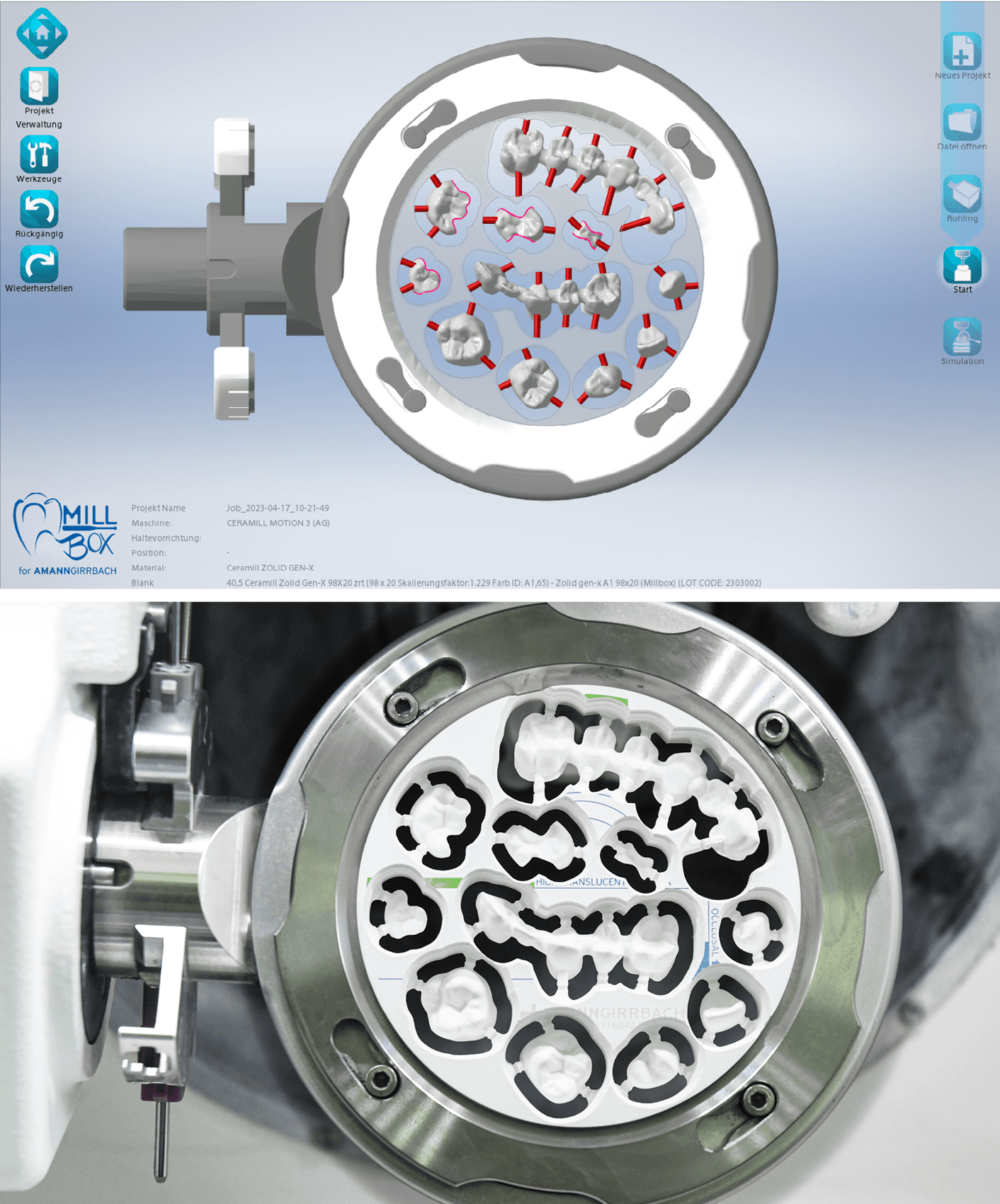

MillBox for Amann Girrbach

MillBox for Amann Girrbach combines the milling expertise and intuitive software interface of MillBox with the powerful Amann Girrbach milling machines, providing users with direct access to the Ceramill Motion 2 & 3. With MillBox for Amann Girrbach, users with MillBox experience can seamlessly connect to their existing MillBox workflow and libraries, allowing for immediate implementation.