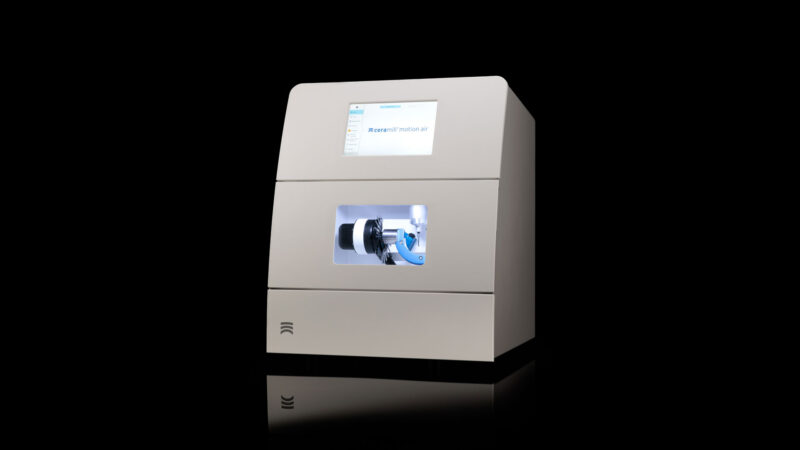

Ceramill Motion DRS – Smart restoration in the dental practice

The 4-axis Motion DRS milling machine offers users maximum treatment versatility in the dental practice and enables high-quality single-tooth restorations even within a single session.

Features

In combination with the Ceramill Mind design software, the Ceramill Motion DRS 4-axis CNC machine can fabricate dental restorations within a single patient session. Owing to the fast-processing strategies, your patients can already leave the dental practice after treatment with a definitive dental prostheses and this with a convincing fit and occlusion. If you wish to take more time for fabrication, it is also possible to postpone starting the work until the evening or the next day. You can have complex work fabricated in your partner laboratory as usual, or have your laboratory assist you with regard to design.

Perfectly complemented in the workflow with…

High process safety for a perfect fit

We offer high process reliability and clinical evidence with the Ceramill Motion DRS milling machine. This ranges from the case creation to the fabrication of the final restoration.

Stand-alone, flexible, safe

The Ceramill Motion DRS stand-alone milling machine is convenient and efficient at the same time. Owing to the integrated control unit, the machine works independently of the design and scanning process. This means that the next patient can already be treated while the machine is working. The water tank and compressor are integrated into the machine, so that all that is needed is a power connection. The intuitive touch screen allows for easy machine control and maintenance. Illustrated work steps guarantee a high level of work safety for you as the user. Smart fitting with an RFID chip allows the 4-axis CNC machine to automatically detect which tool has been inserted and at which position. To avoid mixing up blanks, each blank is scanned and checked for its correctness.

Full range of materials and indications in an integrated workflow. Discover our validated materials.

Technical Data

Global service network in over 90 countries.

In addition to digital support via the Ceramill Helpdesk, we offer you comprehensive on-site technical service, keeping your machines up and running all across the globe.

Get in touchExpert guidance for the highest quality.

Our product specialists will be happy to answer any questions you may have about our equipment and materials. We will be happy to assist you personally with your purchase decision.

Reach outDental expertise available 24/7 on demand.

In the AG.Academy you have access to our entire video archive, filled with tutorials, webinars as well as maintenance guides from our product specialists and experts.

Learn more